What is CRFH Steel?

CRFH stands for cold rolled full hard which refers to steel that has not been fully finished in a cold reduction mill. The full hard designation indicates that the steel has not been annealed, meaning it is more rigid and less malleable than other types of steel. This makes it ideal for applications with high levels of strength and durability.

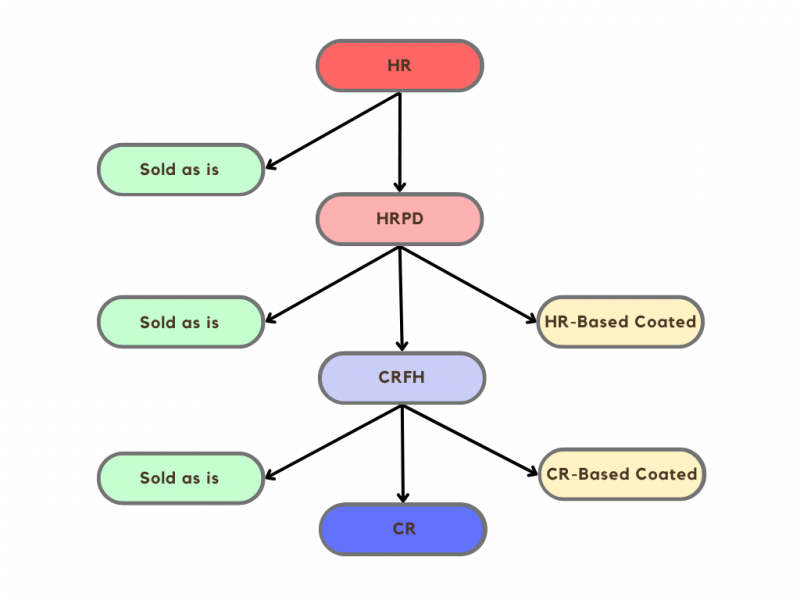

Steel processing begins in the mill by rolling a hot rolled slab to hot rolled coil, followed by a pickle bath to remove the scale and imperfections. Once pickled, the steel is sold as hot rolled pickled dry (HRPD), hot rolled pickled and oiled (HRPO), or it is pushed further to become hot rolled-based coated products.

Processing the steel in a cold reduction mill to reduce its gauge/thickness makes the steel thinner. Once reduced, the coil is officially CRFH. This product can be sold as is. However, as a prime product, it accounts for a very small segment within the overall mill portfolio.

The steel can be processed further to become a CR-based coated product (with an additional coating stage) or a finished CR product after annealing and finishing.

Cold-rolled full hard steel is a by-product of flat-rolled steel that can be utilized in an unfinished state or processed further as a finished product.

Cold rolled full hard can also be a downgraded application for an alternative product. Non-prime CRFH can be flagged during the production process for various qualitative reasons. However, it’s important to note that secondary/excess CRFH doesn’t always stem from issues with prime CRFH.

What is CRFH steel used for?

As mentioned previously, prime CRFH is not a large product group. It is typically used in applications where limited bending or forming is needed. It is often used in the construction and packaging industries but requires very specific specifications as it is part of the structural integrity of the end product.

Cold rolled full hard is not a familiar product line to most, and given its specific requirements due to its non-standardized production, it requires a partner with experience and support to best apply it.

Not only does Mainline Metals ensure your cold rolled full hard steel is designed to meet your exact standards, but our culture is also centered on customer relationships, and we are recognized as an industry leader. We are well-versed in CRFH steel and matching potential products to applications that benefit from CRFH.

Contact us to learn more.

The benefits of CRFH steel:

- Cold-rolled full hard steel is economical compared to finished CR if the product meets the end-user specs.

- Turnkey flat roll mills with products beyond HR sheets and hot rolled pickled oil metal can produce CRFH. Most mills manufacture this because they make other products requiring CRFH as a semi-finished product.

- CRFH is hard and significantly stronger than hot-rolled steel.

- Full hard cold rolling offers the tightest tolerances that can significantly reduce the thickness of the steel.

- It has an improved surface finish that is smoother and has fewer surface imperfections than hot-rolled steel.

- The small number of users compared to producers of CRFH results in inherent availability.

The limitations of CRFH steel:

- Cold rolled full hard steel is unannealed, which results in higher physical properties and hardness levels.

- When compared to hot-rolled steel, CRFH typically costs more money to produce.

- It is refined, and typically dry surface runs the risk of oxidation, which makes it more susceptible to corrosion.

- Non-prime CRFH often has yet to go through the shape correction process, which may hinder its application.

- It has limited application compared to finished CR and coated products.

- Since it can be a by-product, it may have several quality issues and defects that vary based on how it was made.

At Mainline Metals, we specialize in guiding our customers on available products to meet their applications while advocating for their economic, qualitative, or volume-based needs.

← Back To News