Home / Mill Surface Defects / Rolled-In Material

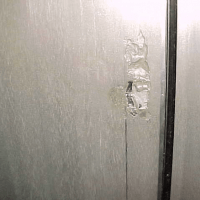

This defect is the appearance of debris thrown in on the coil’s mill edge and pressed into the surface. It is also known as rolled-in-metal or laminated edge. It is caused by a build-up of galled steel on the side guides of a hot mill stand or hot mill down coiler. The galled up steel can spall off during cooling that occurs between the coiling of each coil or the buildup can be abraded off by the next coil rolled. This photo shows the defect on a coil that was galvanized over (1) and hot rolled and pickled (2).