Home / Mill Surface Defects / Sags in Coating

What is it?

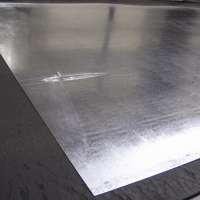

This defect happens when the coating forms a sag in a confined area of the strip. The defect is usually caused by poor temperature control of the strip or pot. Borderline cold or excessive temperature can create this condition of coating flow over the complete surface of the strip. The sag develops due to a disruption of coating flow during processing.