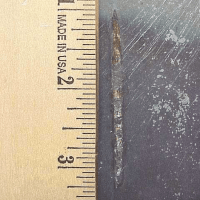

A tear-drop shaped defect that’s elongated in the rolling direction of the steel. It commonly appears as a sliver after cold rolling or as a crater in the tear-drop shape after pickling or hot rolling. This defect is also called mold powder spots, mold powder inclusions, or white spots. The defect is from calcium aluminate that solidifies during casting. Calcium aluminate is typically liquid at steel making temperatures unless too much oxygen or calcium is present. Oxidizing the steel or adding too much calcium can result in this defect.

Home / Mill Surface Defects / White Surface Inclusion